Vacuum Dewatered Flooring (VDF) is a special type of Flooring Technique to achieve High Strength, Longer Life, Better Finish and Faster Work. This type of floor is suitable for high abrasion & heavy traffic movement. TheVDF is a system for laying high quality concretefloor. Concrete Vacuum Dewatering System.

VDF FLOORING

What is VDF Flooring or Vacuum Dewatered Flooring

VDF Flooring stands for Vacuum Dewatered Flooring. This is a special technique to do the Concrete Flooring to increase the Compressive Strength, Tensile Strength, Abrasion Resistance and to minimize the Shrinkage and Floor Wraps. VDF Flooring results in High Strength, Longer Life, Better Finish and Faster Work. This type of floor is suitable for high abrasion & heavy traffic movement.

The Vacuum Dewatered Flooring or VDF Flooring is a system for laying high quality concrete floors where the key is Dewatering of Concrete by Vacuum Process wherein surplus water from the concrete is removed immediately after placing and vibration, thereby reducing the water: cement ratio to the optimum level.

Procedure of VDF Flooring

Tying Line Dori (Threads) as per the slope requirements

Laying Guide Rails to every 4 meters using MS Channels or as required in straight lines along the Line Dori, taking levels as per the slope and fixing them using concrete also called grouting and left to set for a minimum of 24 hours

Pouring the concrete in between the channels and spreading using Shovel or Hoe (Kudal/Parah)

Vibrating the concrete with a poker vibrator especially to the sides of the panels

Surface Vibration the concrete using Double Beam Screed Vibrator running over the guide rails twice to achieve maximum compaction for RCC with double mats

Final levelling of the concrete using the Straight Edge/Bull Float/Aluminium Bottom (Fanti/Baddha)

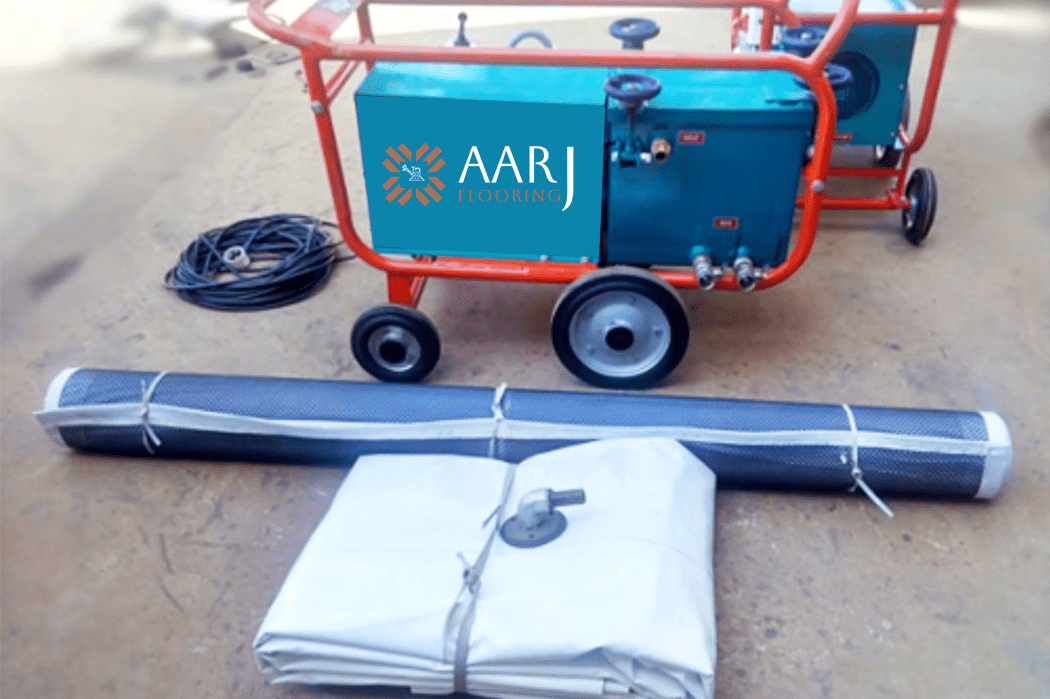

A system of lower mats & top mat is laid on the green concrete & this is attached to a vacuum pump. This draws out surplus water if any. (We strongly oppose dewatering of RMCs. RMCs have water cement ratio already maintained to its minimum possible level by addition of admixtures. Further dewatering decreases the water cement ratio below the required level thereby causing undulations in the surface, loss in strength and formation of cracks.)

The concrete is left to stiffen. When the base concrete has stiffened to the point when foot traffic leaves an imprint of about 3-6 mm and any bleed water should now have evaporated, but the concrete should have a wet sheen, Floor Hardener is applied at an even application rate of 3-7 Kg/Sqm or as per the requirement of the floor.

Application of Power Floater on the surface until the surface is sufficiently compacted & levelled with no major lines appearing any more

Final finishing using Power Trowel and trowelling until the required finish is achieved. Finish could be any of the Smooth Finish, Sand Finish or Line Finish.

Benifits of VDF Flooring – Vacuum Dewatered Flooring

Increased Compressive strength by more than 50%.

Reduced Cement consumption by more than 30% as no cement is required separately for finishing.

Increased Abrasion resistance by more than 50%.

Increased wear resistance.

Minimum dusting & crack formation.

Minimum dry and plastic shrinkage and floor wraps.

Uniform homogeneous floor with High flatness accuracy.

Lower water permeability due to increased density.

High early strength minimizes damage on newly cast floors.

Earlier utilization and Reduced maintenance cost.

Typical Application Areas of VDF Flooring

Warehouses, Godowns

Roads, Sports Courts

Cellars, Parking Areas

Production Areas

Pharmaceutical Companies

As the base floor for Epoxy & PU Floorings